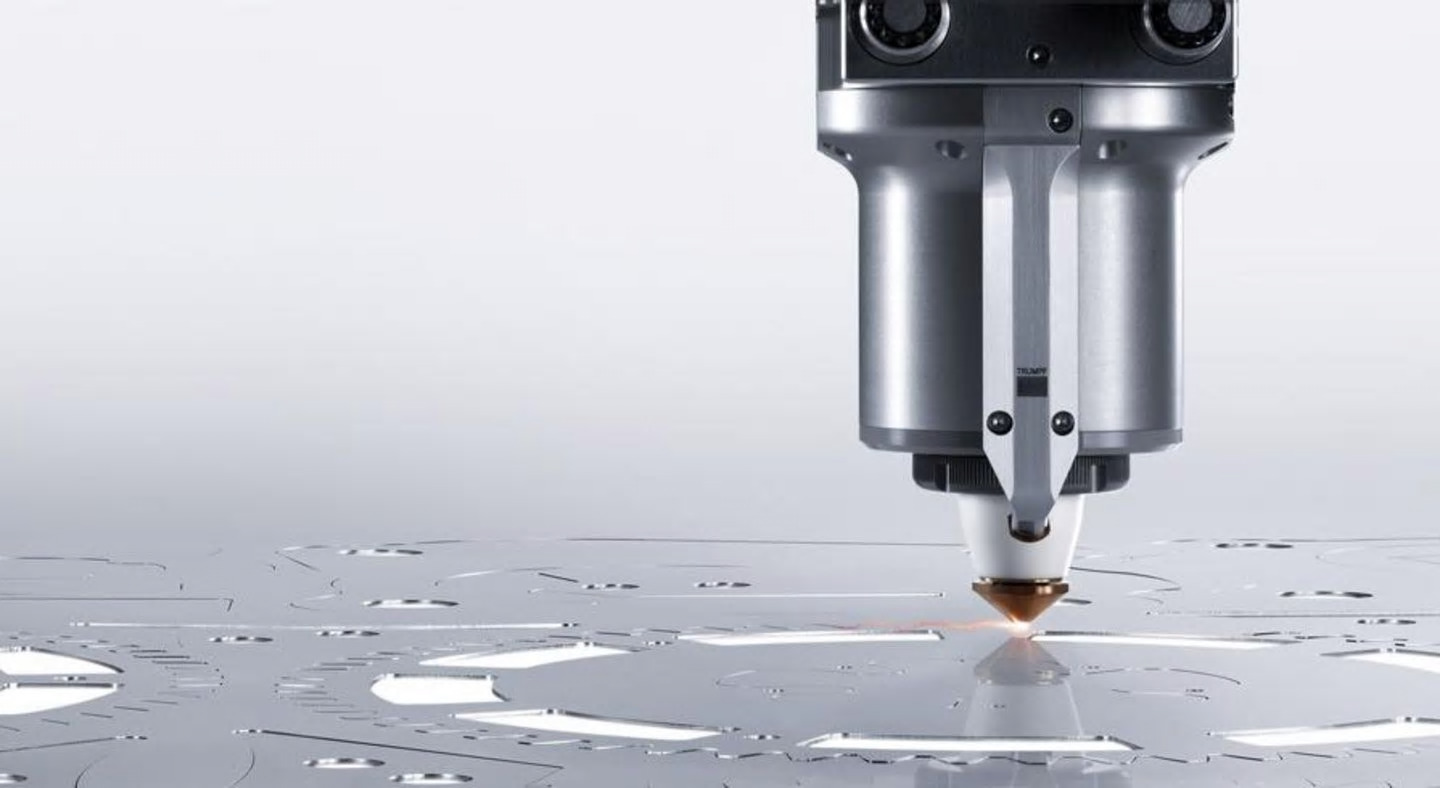

TRUMPF LASER CUTTING SYSTEMS

TRUMPF lasers are known as the world leader in CO2 metal cutting lasers. Metal fabricators and steel service centers around the world have enjoyed the leading technology offered by TRUMPF for years. TRUMPF lasers are available in a wide range of laser powers, up to 20,000 watt. When cutting thin sheet metal, we offer the fastest processing speeds, or when cutting thick plate, we can offer power to process those difficult materials. Most of the TRUMPF lasers are built here in the USA. Since most of our machines and resonators are manufactured from the ground up in our Farmington, CT facility we can offer our customers the best of parts availability, and service after the sale.

TRUMPF builds CO2, Yag, fiber, and Disk lasers for 2D metal cutting, 3D metal cutting, laser welding, laser marking, laser cladding, heat treating and other various applications. TRUMPF lasers are the preferred choice for the metal fabrication and metal working industry.

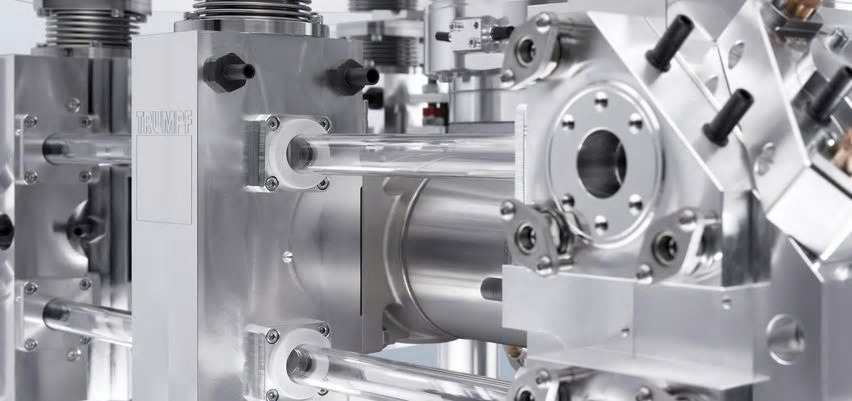

TRUMPF TruFlow lasers are available from 200 watt to 20,000 watts of power. TRUMPF CO2 laser are built for their extremely high reliability and cost-effectiveness. Ultra-modern, maintenance-free radial turbo blowers on magnetic bearings offer superior efficiency in gas circulation, making for excellent cooling and an optimal degree of efficiency.

The TruFlow laser series is modular in design and is based on a scalable concept. Over a thousand new systems with TruFlow lasers are installed worldwide every year. Besides the standard units, special solutions are also available for specific application fields. HQ lasers feature a very high beam quality close to the physical limit. TruFlow lasers all feature the same user-friendly controller with the possibility of tele diagnostics.

We also offer all lasers for OEM integration in your own systems.

TRUMPF offers a complete line of TruDisk Fiber laser technologies. TruDisk Fiber lasers offer a large advantage over other fiber laser technology due to the Disk. With Disk technology you have the ability to easily upgrade, replace diodes, and protect from any back reflection that is common in one micron cutting and welding applications. TRUMPF builds the entire assembly from the diodes, to the disk, to the delivery system. All TruDisk Fiber systems offer sensors to monitor the laser for performance. Thus, maintenance can be scheduled. Tele-diagnostics can be performed remotely to minimize down time. TRUMPF builds a wide range of units up to 16,000 watts. TruDisk Fiber lasers can be coupled with some of TRUMPF's TruLaser metal cutting laser or robotic applications for welding.